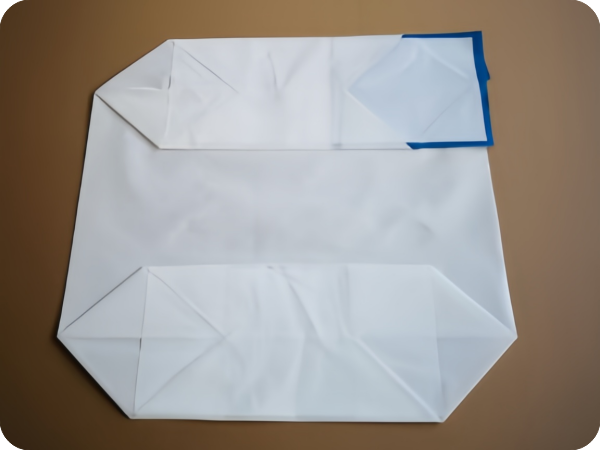

Process: The bag bottom material is fused or bonded together using heat sealing or adhesives.

Features: Forms a fully sealed structure, providing excellent moisture and air leakage resistance; smooth appearance and good printing results. Widely used in valve bags and stand-up pouches requiring high barrier properties in the food, chemical, and plastics industries.

Core Difference: Sewn bottoms prioritize strength, with sealing as a secondary consideration; glued bottoms prioritize a complete seal while also maintaining strength.